Hazardous location areas are defined by taking into account the different dangers presented by potentially explosive atmospheres. This enables protective measures to be taken which account for both cost and safety factors.

The IEC classification system, used throughout much of the world outside of North America, varies from the traditional NEC Class/Division system in that it recognizes three levels of probability that a flammable concentration of material might be present. These levels of probability are known as Zone 0, Zone 1, and Zone 2. The Zone designations replace the Divisions found in the NEC system. No exact correlation can be made between the Zone and Division designations.

Zone 0:

In which ignitable concentrations of flammable gases or vapors are:

- Present continuously

- Present for long periods of time

Zone 1:

In which ignitable concentrations of flammable gases or vapors are:

- Likely to exist under normal operating conditions

- May exist frequently because of repair, maintenance operations, or leakage

Zone 2:

In which ignitable concentrations of flammable gases or vapors are:

- Not likely to occur in normal operation

- Occur for only a short period of time

- Become hazardous only in case of an accident or some unusual operating condition.

Read more: Zone 1 & 2 Explosion Protection

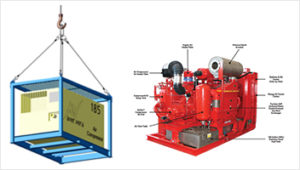

The ATEX explosion protection conversions of the diesel engine for use in areas classified as Zone 1 (2G) and Zone 2 (3G) provide the electrical and mechanical protection of the diesel engine, removing the risk of spark ignition and hot surfaces.

The main consideration for protection includes:

- Temperature class T3

- Gas group IIA/IIB

- Various Ex explosion technique suitable for protection of diesel engine operation

- Cooling of the exhaust gases

- Protection of standard electrical system

- Control panel for the engine management

- Earth bonding to frame

Read more: ATEX explosion protection conversions